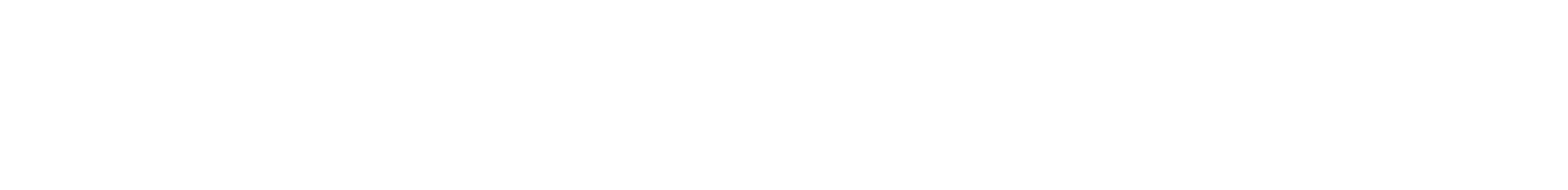

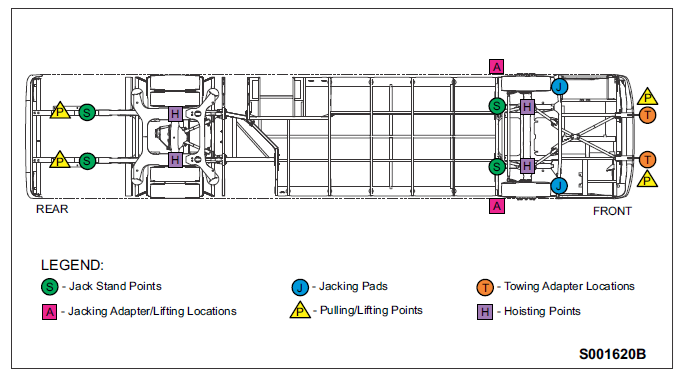

- High Voltage Lithium-ion Batteries on Roof and in Rear Compartment

- High Voltage Equipment on Roof, in Rear Compartment and Underneath the bus

- High Voltage Cables on Roof, in Rear Compartment and Underneath the bus

Tap to jump to each section below

Click to enlarge

-

Secure vehicle (shift to neutral and apply parking brake).

-

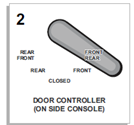

Open the front and rear passenger doors. Direct all passengers to a safe area, away and upwind from the vehicle.

-

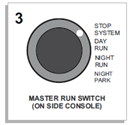

Shutdown the vehicle using the Master Run switch on the driver’s side console.

-

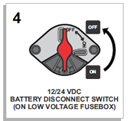

If it is safe to do so, turn the 12/24 VDC Battery Disconnect switch located behind the Battery Disconnect and High Voltage Interlock switch access door to the OFF position.

-

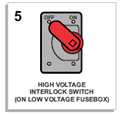

Turn the High Voltage Interlock switch located behind the Battery Disconnect and High Voltage Interlock switch access door to the OFF position.

-

Chock wheels if safe to do so.

-

Report actions taken to the first responders upon arrival.

-

Be familiar with and follow applicable National, State/Provincial and Local Fire and Safety Regulations.

-

This is an Electric Drive vehicle which contains 600 VDC and 230 VAC high voltage equipment in the rear compartment, on the rooftop, and interior of the vehicle.

-

High voltage cables can be identified by an orange outer covering.

-

Use extreme caution when handling, orange high voltage cables or Electric Drive components, as this could result in severe injury or death!

-

A High Voltage Interlock switch protects all circuits and components, BUT it is still possible to receive a fatal electric shock from the system!

-

DO NOT cut High Voltage Cables.

-

If working near high voltage cabling or components, use 1,000 VDC electrical gloves, rubber-soled shoes and make sure you and the surrounding area are DRY!

-

Never breach or remove the ESS cover under any circumstances, including fire. Doing so might result in severe electrical burns, shock, or electrocution.

-

The shutdown procedure should interrupt all power to the HV cables and isolate the battery modules. The battery modules within the battery enclosures will remain energized. The batteries are not discharged with the High Voltage Interlock Switch, they are disconnected and taken off-line but will remain charged. HV is present at the battery modules.

-

If the vehicle is connected to the charging station, the charging station should be de-energized using circuit breakers located behind the charging cabinets.

-

Pull the breaker handle down to de-energize power to the chargers.

-

The Kirk Transportation building has 3 individual breakers for each charging cabinet. These are located inside the building along Bonaparte Avenue, next to the cabinets.

Lithium-ion batteries use a carbon negative electrode and a Lithium Cobalt Manganese Nickel Oxide positive electrode. The electrolyte is a solution of lithium hexaflourophosphate in a mixture of organic solvent. Exposed electrolyte solution is corrosive and may be flammable in sufficient concentration.

-

DO NOT USE Class D fire extinguisher.

-

USE CLASS A, B or C fire extinguishers for small fires.

-

USE WATER in large amounts for large fires.

-

Wear full protective clothing including helmet, face mask and self-contained positive pressure or pressure demand breathing apparatus.

-

Exposure to excessive heat may lead to venting or rupture of the sealed battery, exposing the internal components which are corrosive and flammable.

-

Establish a 20’ or larger perimeter if fire or smoke is present at the Energy Storage System (ESS.) PPE must be worn within the perimeter.

-

Proper PPE gear is required if smoke is present, including a self-contained breathing apparatus. Assume that smoke, regardless of the source, is toxic.

-

Extinguish small fires that do not involve the high voltage battery using typical vehicle firefighting procedures.

-

If there is heat or smoke present at the battery enclosure, there is a potential battery fire.

-

The smoke is toxic and flammable.

-

Do not remove or breach ESS or HV enclosure covers under any circumstances including fire. Doing so might result in severe electrical burns, shocks, or electrocution.

-

Use large amounts of water to cool the outside of the enclosure.

-

A battery fire can take up to 24 hours to burn out.

-

Use large amounts of water to extinguish battery fires. Establish an additional water source as required.

-

Use a thermal imaging device to ensure all heat sources are extinguished. A battery fire has the potential to re-ignite. Use thermal imaging device to ensure that the high voltage battery is completely cooled before towing or moving the vehicle. The battery must be monitored for at least one hour after it is found to be completely cooled.

-

Smoke or steam indicates that the battery is still heating. Do not release the vehicle to second responders, such as the law enforcement and towing personnel, until there has been no heating detected for one hour.

-

Always advise second responders that there is a risk of battery re-ignition.

-

A battery fire is an extremely unlikely event.

-

The ESS system is designed to prevent a fire from starting inside the battery packs and warns the operator of a fire inside the battery enclosures.

-

The ESS battery pack enclosures are toughened to resist external fires, hard short circuits, internal flooding, and over-heating.

-

Each battery has a cooling plate separating each cell to manage cell temperature.

-

The battery’s voltage, current, state of health and temperature is actively monitored.

-

If a battery pack is out of limits, the system automatically disconnects the damaged string connecting the faulty battery pack.

-

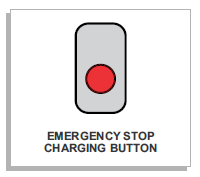

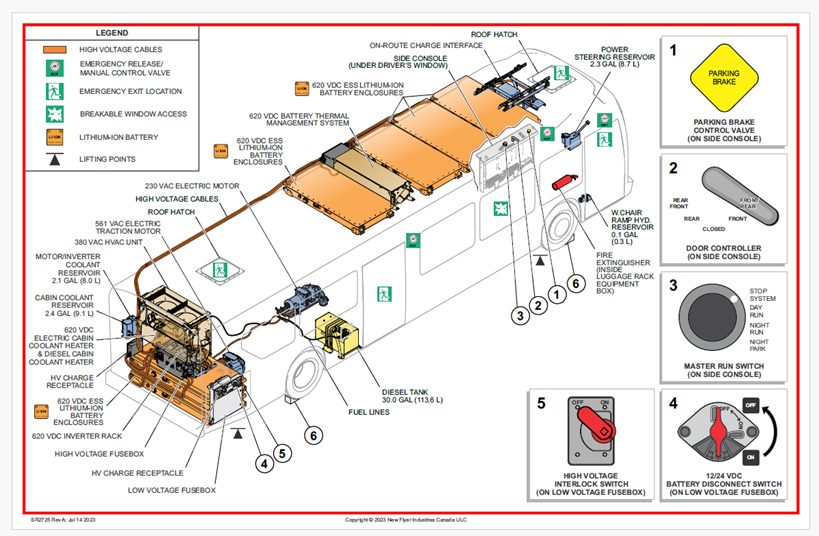

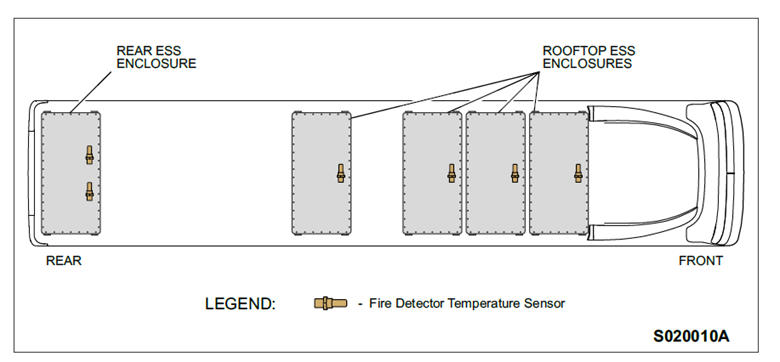

In case of an enclosure fire, temperature sensors in the fire detection system warn of emerging thermal events, trigger a stop system, and show a warning on the instrument panel.

-

Each of the ESS enclosures has fire detectors.

Click to enlarge

-

This vehicle has automatic fire suppression system. There are fire detection sensors and suppression nozzles in the rear ESS compartment, and a fire extinguisher cylinder behind the streetside corner pillar.

-

If a fire is detected, the system will release fire suppressant from the nozzles and sound an alarm. You can also manually activate it by pulling a pin on the driver's overhead panel.

-

The Electrolyte and its fumes are toxic. Wear full protective clothing, including helmet and face mask, and self-contained positive pressure or pressure demand breathing apparatus.

-

If possible, stop or minimize the flow of battery electrolyte.

-

Contain spillage from a damaged or open cell or battery with dry sand or an absorbent cloth.

-

Battery Electrolyte is classified as a water pollutant under the Clean Water Act and should be prevented from contaminating soil or from entering sewage and drainage systems which lead to waterways.

-

Eyes - Not dangerous with normal use. Eye contact with contents of an open battery can cause severe irritation or burns to the eye.

-

Skin - Not dangerous with normal use. Skin contact with contents of an open battery can cause severe irritation or burns to the skin.

-

Inhalation - Inhalation of materials from a sealed battery is not an expected route of exposure. Material emitted from a ruptured battery may cause respiratory irritation.

-

Ingestion - Swallowing of materials from a sealed battery is not an expected route of exposure. Swallowing the contents of an open battery can cause serious chemical burns of mouth, esophagus, and gastrointestinal tract.

-

Eye contact - If eye comes in contact with contents of an open or damaged cell or battery, immediately flush the contaminated eye(s) with lukewarm water for at least 30 minutes. Get medical attention immediately. Rinse eye with calcium gluconate solution (1%) until arrival of doctor. Continue rinsing.

-

Skin contact - If skin contact with contents of an open battery occurs, immediately flush with lukewarm water for at least 30 minutes. Thoroughly wash (or discard) clothing and shoes before reuse.

-

Inhalation - If contents of an opened battery are inhaled, remove source of contamination, or move victim to fresh air and seek medical advice.

-

Ingestion - If ingestion of contents of an open battery occurs, rinse mouth thoroughly with water. DO NOT induce vomiting. If victim is fully conscious, give a cupful of water. Never give anything by mouth to an unconscious person. If vomiting occurs, keep head lower than the hips to help prevent aspiration. Call a physician or poison control center immediately.

ONLY enter the vehicle if it is safe to do so. ONLY enter through the entrance door to retrieve the chock blocks, apply the parking brake, and access the Master Run switch. Alternatively, if it is not safe to enter the vehicle, the parking brake and Master Run switch may be accessed through the driver’s side window.

-

Follow Emergency Shutdown and Evacuation Procedure.

-

Assess vehicle for risks.

A major collision from the side or rear could result in damage to high voltage cables, batteries or other reservoirs containing hazardous liquids. Ensure the High Voltage system is switched off at High Voltage Interlock Switch.

-

Avoid contact with High Voltage (HV) components. Refer to the Emergency Responder Quick Reference Guide for information on the location of High Voltage components.

-

Wear full protective clothing including helmet, face mask and self-contained positive pressure or pressure demand breathing apparatus.

-

Attend to any first aid needs.

-

Contain any spills or fluid leaks using sand or other absorbent material.

High Voltage Cables are routed on the roof. If these cables become damaged or exposed during an accident, they may remain live. Ensure the High Voltage system is disabled using the High Voltage Interlock switch before working in the area of damaged cables.

-

Access to passengers can be gained through the entrance and exit doors, side windows, or the roof hatch.

Proper PPE should be worn when assessing damage around battery enclosures and HV components. If there is damage to an ESS enclosure or battery module, an assessment needs to be made to determine if the vehicle can be safely towed.

The batteries are still holding a charge and HV is present at each module.

With the HV system disconnected, the HV cables should not pose a risk during towing. Properly HV trained personnel in proper PPE gear can remove the MSD’s at each string to further ensure isolation of the battery packs if component damage is severe and there is concern the automatic disconnects are damaged.

-

If the vehicle is submerged (with water above the bottom of the rear bumper), wear proper PPE gear with a minimum arc flash rating of 8cal/cm2 before approaching the rear bumper, or ESS compartment area.

-

If the ESS is submerged or partially submerged, a voltage hazard exists at the batteries and HV energized components. Avoid contact with HV components, cabling, or service disconnects on a submerged vehicle.

-

The front and sides of the vehicle do not pose a HV risk if partially submerged.

-

The vehicle should be retrieved from the water before other work is performed.

-

Water levels below the bottom of the bumper should not pose any HV risk. In some instances, small bubbles may be seen coming from an immersed HV battery. This is referred to as micro-bubbling. This DOES NOT indicate a shock hazard and DOES NOT electrify the surrounding water.

-

Follow Emergency Shutdown and Evacuation Procedure.

-

Assess vehicle for risks.

-

Avoid contact with High Voltage (HV) components.

High Voltage Cables are routed on the roof. If these cables become damaged or exposed during an accident, they may remain live. Ensure the High Voltage system is disabled using the High Voltage Interlock switch before working in the area of damaged cables.

-

Attend to any first aid needs.

-

Access to passengers can be gained through the entrance and exit doors, side windows, or the roof hatch.

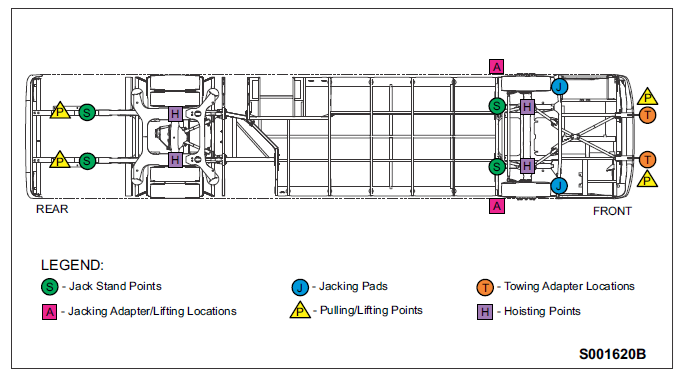

If the vehicle is submerged or involved in a collision and needs to be moved for salvage or access, only connect to the points on the frame designated for pulling the vehicle.

Towing Procedures:

-

Bus can be towed from the front using either the flat or raised method.

-

New Flyer recommends flat towing method to minimize the likelihood of damage to the vehicle.

-

For flat towing, vehicle must be prepared by removing either the driveshaft or both rear axle shafts.

-

Extra care must be taken when using the raised towing method to ensure adequate ground clearance at the rear of the vehicle.

-

Towing adapters must be used for flat or raised towing to provide the proper offset and clearance and to allow the attachment of towing equipment.

-

Rear towing is not recommended due to insufficient ground clearance at the front of the vehicle and the problem of locking the front wheels in a straight position.

For jacking and hoisting support, refer to the diagram for specified locations.

Click to enlarge

-

Antifreeze - Final Charge 50/50 Premix w/ Bitrex - 36.0 gal (136.3 L)

-

Power Steering - MSDS #455936 - Transynd - 4.0 gal (15.1 L)

-

Hydraulic Fluid - MSDS #3009356 - Duradrive HD Synthetic - 0.5 gal (1.9 L)

-

Ultra Low Sulphur Diesel - MSDS #320-110 - 30.0 gal (113.6 L)